Slot Partial Discharge

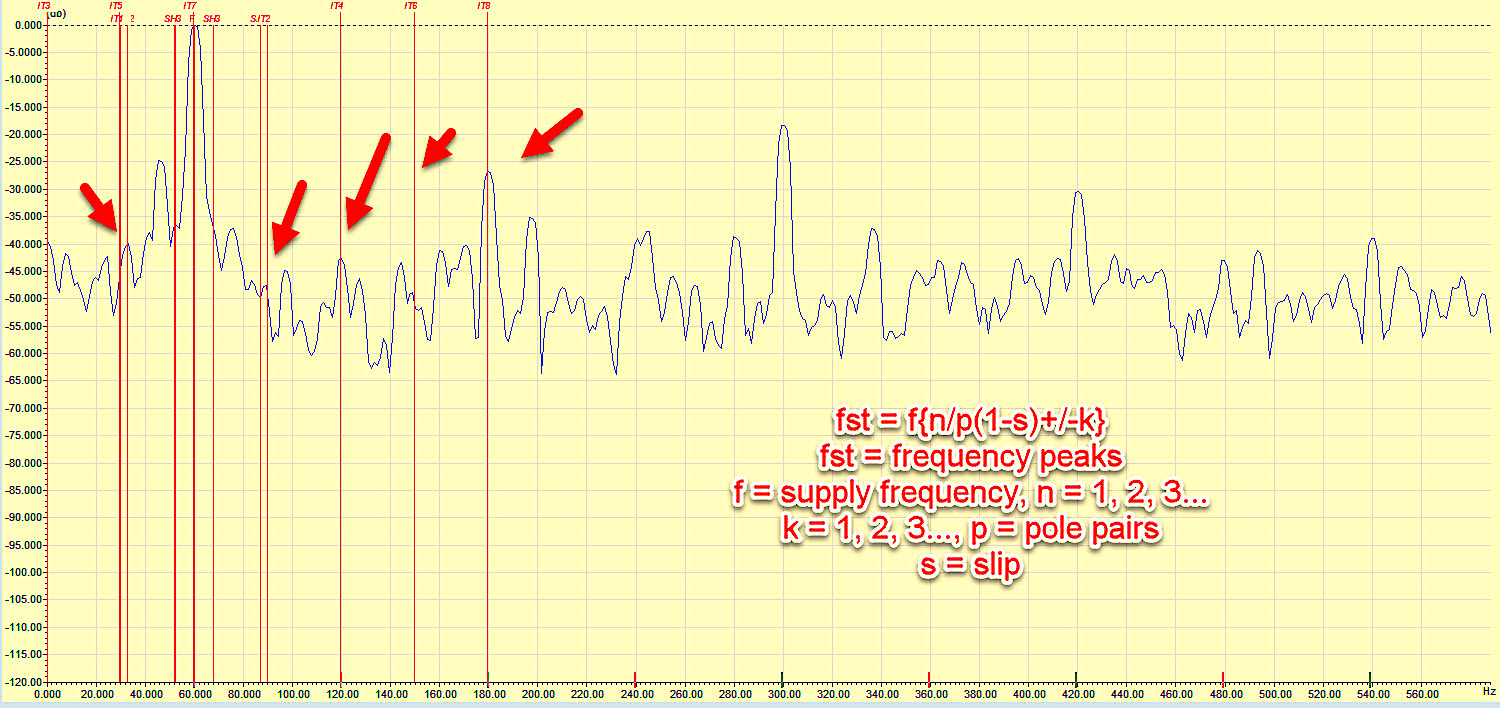

Phase-resolved partial discharge patterns are useful in identifying the most important failure mechanisms of stator windings. The first systems to monitor partial discharges during regular operation were developed in the early 1970’s by Westinghouse in the USA and Ontario Hydro in Canada. The stimulus for this development were problems, at. Partial discharge pulses characteristically have rise times that are.

- Partial discharge (PD) occurs if dielectric strength within a certain region of the insulation of an electric device is locally exceeded, but the surrounding insulation is strong enough to prevent total breakdown. In order to understand the occur-rence of PD and the response of electrical network to the excitation by discharge.

- Slot discharge refers to the observation that partial discharges (PD) may occur on the surface of the bar (half-coil), either within the stator core slot, or just outside of the slot. Figures 1-2 show photos of bars experiencing slot discharge considered as fairly serious and corrective action would be considered necessary. There are three.

- Slot discharge refers to the observation that partial discharges (PD) may occur on the surface of the bar (half-coil), either within the stator core slot, or just outside of the slot.

Contribution of Electrical-Thermal Aging to Slot Partial Discharge Properties of HV Motor Windings

Abstract

During the operation of HV motor, the abrasion of stator windings because of vibration caused by electromagnetic force will lead to slot partial discharge (PD). Furthermore, the superheat induced by overcurrent or poor heat dissipation will aggravate the slot PD. To understand the developing process of slot PD and comprehend the influences of aging factors on slot PD properties, two discharge bar models were made under electrical-thermal aging. At triple the rated line-to-earth voltage of 6 kV, two stator bars were aged for 37 days under different temperatures. The slot PD was measured during different aging stages, and visual observations of the insulation and stator core surface were made at the beginning and the end of aging. The experiment results indicate that electrical-thermal aging has a significant impact on the slot PD activities. The slot PD was intense under higher thermal stress, and the surfaces of insulation and stator core were oxidized after the long-time aging. This study can provide a judging basis for fault diagnosis of HV motors.

Slot Partial Discharge Definition

- Electrical-thermal aging;

- Slot partial discharge properties;

- HV motor windings